Help! My Spa Pump is Leaking!

It happens to all spa and hot tub owners at one time or another. You first notice that the spa seems to be needing more refill water than usual, and then you notice a wet spot around the spa pack equipment, and it hasn't rained in a while...

The spa pump is just one of the areas that can leak in your spa, but it is one of the most common. That's because your pump shaft is spinning around at speeds of up to 3450 rpm - that's a lot of friction and a lot of heat generated.

Spa pumps can also leak from freeze damage or from experiencing a water hammer effect. Let's delve into 3 places a spa pump could be leaking - and what to do about it.

LEAKING SHAFT SEAL:

The mechanical shaft seal wraps around the spinning motor shaft, at the rear of the volute. The design of the two piece shaft seal allows the shaft to spin freely, without leaking. Spa pump seals can fail, especially if the pump was run dry, or if valves are closed while the pump is running, known as deadheading, which creates a water hammer effect when the water suddenly stops in the pipes. If the shaft seal is leaking the water will be running down the backside of the volute and dripping off of the bottom center, in tell-tale fashion.

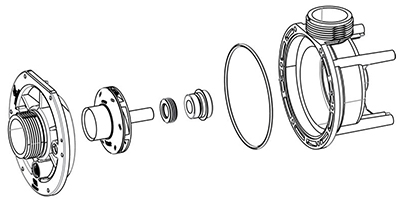

To replace a hot tub pump shaft seal, you need to open up the wet end of the pump, known as the volute. Clamp the shaft tightly while you spin off the impeller. There you will see one half of the shaft seal (the spring half) on the impeller stem, and one half of the seal is press fit into the back of the volute, where the motor shaft enters. Remove the bolts that connect the volute to the motor. Knock out the rubber and ceramic ring in the volute, and press fit the new seal half in place, being careful to keep it clean. Slide the other half of the seal, the spring half, off of the impeller, and slide the new one on in the same direction. They should both fit very snugly, if you have the right shaft seal (these are not universal, each pump has it's own seal).

LEAKING UNIONS:

The unions are those large white rings that are threaded onto the pump, one where the water enters and one where it exits. A spa union is a 3-part connector, with two halves - and a large ring or nut to tighten the halves together. One side usually has male threads which screw into the pump. In between the two halves sits a very important o-ring, which can become dislodged if the union is opened or tightened while there is water rushing out.

Another type of leaking union occurs when the threads that are screwed into the exit of the pump have heated up and shrunken slightly. This can happen if the pump runs dry, or otherwise generates enough heat. The tell tale sign to look for is water leaking around the union which carries water out of the pump. When it happens on the incoming union, the one that brings water into the pump, this will usually draw air when the pump is running, and leak water when the pump is off.

In both cases, you can quickly repair a leaking union, by reseating or replacing a union o-ring, or replacing a union half that has shrunken.

LEAKING VOLUTE:

The third and final type of leaking spa pump is the leaking volute, aka impeller housing. The volute can become cracked if left full of water at freezing temperatures, which then drains the spa for you as it thaws.

The volute can also become damaged by a water hammer effect, caused by closing off valves after the pump while the pump is running. If your volute has cracked, that should be obvious, it's usually a fast leaker that is hard to miss, and different than a leaking union or shaft seal.

To repair a cracked volute, you can replace just the volute parts that are cracked (front or rear volute half) or you can buy the entire wet end, center discharge wet ends or wet ends for side discharge pumps. The entire wet end includes both volute halves, impeller, diffuser and seal; use if you are more comfortable replacing the entire shebang.